Trouble Shooting »

Lining Failure

Indicator

No drive. With the clutch engaged the vehicle increases in RPM but does not move. May even have difficulties disengaging the clutch.

Causes

1. Incorrect clutch free travel

2. Worn or damaged clutch control components (Fork, Pivot Ball, Cable, Master Cylinder and/or Slave Cylinder)

3. Oil/Grease contamination

4. Driver error

Effect

The clutch has exceeded normal operating temperature resulting in the lining material to carbonize. When clutch disc linings carbonize the bonding resin in the lining material melts causing the material to break down.

Action

1. Replace clutch kit.

2. Adjust the clutch control to manufacturers specifications.

3. Inspect all clutch control components (repair or replace)

4. Inspect all oil seals for leaking. Replace if necessary.

5. Driver education.

Total Failure

Indicator

Severe bearing noise when foot is on the clutch. May even result in the pedal sticking down

Cause

1. Incorrect clutch free travel (bearing has excessive pre-load on the clutch diaphragm spring)

2. Clutch control failure (Cable, Hydraulic, Fork, Pivot Ball or Bearing Guide)

3. Driver error (The driver resting their foot on the clutch pedal whilst driving)

Effect

Incorrect release bearing clearance causes loss of grease due to significant heat. This results in total failure of the bearing

Action

1. Replace or repair any worn clutch control components

2. Replace clutch kit

3. Adjust the clutch cable or master cylinder to the manufacturer’s specifications

4. Driver education (Don’t rest the foot on the clutch pedal)

Insufficient Lubrication of the Spline

Indicator

Difficult to dis-engage gears

Cause

1. Insufficient lubrication of the clutch disc spline

2. Dirty/Contaminated splines on the gearbox

Effect

Dry splines on the clutch disc and red dust may be present

Action

1. Clean the input shaft splines removing any old grease or old clutch dust

2. Lubricate the splines (refer the fitting video https://www.youtube.com/watch?v=OrH7gCmjF-o)

CSC Contamination

Indicator

Concentric Slave Cylinder (CSC) leaking/no pedal

Cause

1. The CSC has been exposed to fluid contamination with either engine or transmission oil compromising the seal.

2. Incorrect fluid used in the hydraulic system

Effect

The internal rubber seal swells due to the contamination and in some cases splits

Action

1. Identify why the CSC has oil contamination and repair the leak (engine: rear mail seal, rocket cover gaskets – transmission: front shaft seal)

2. Thoroughly clean the back of the engine and transmission bellhousing to remove any oil residue

3. Replace the CSC

4. Flush the clutch hydraulic fluid system using the manufacturers recommended fluid.

Slipping

Indicator

Whilst in 4th gear the engine is revving but the speed of the vehicle is not increasing

Cause

- There is incorrect clutch free travel

- The clutch control mechanisms are faulty (fork, pivot ball, cable, and/or clutch hydraulics

- Worn out clutch kit

Effect

The clutch diaphragm has been partially disengaged causing the disc to spin within the housing or the disc thickness as reduced enough for it to slip.

Action

- Correct the clutch free travel as per manufacturers specifications

- Replace any worn or damaged components

- Renew the clutch kit

Clutch Slipping

Indicator:

Clutch Slipping

Cause:

1. The clutch hydraulics may have a failure

2. Incorrect clutch free travel setting

3. Vehicle is constantly overloaded

4. Incorrect clutch for the application

5. Poor driving practices (the driver resting their foot on the clutch pedal when driving)

6. The clutch is worn beyond its service life

Effect:

The vehicle is unable to drive correctly and has a burning smell coming from the gearbox area.

Action:

1. Assess the vehicle loads and conditions the vehicle is being used for.

2. Driver training and education if necessary

3. Check the vehicle hydraulics. This can be done by either undoing the bled nipple on the slave cylinder or pushing the slave cylinder pushrod back by hand. If there is residual line pressure the fluid will “shoot” out when cracking the bleeder. If trying to push the pushrod back again holding line pressure will prevent the pushrod from moving in the slave bore. In both cases it would identify a master cylinder problem or a clutch pedal over adjustment.

4. Check the clutch free travel settings. The clutch pedal should have some “free” movement at the top of the pedal.

5. If the clutch is worn beyond its service life it will need replacing.

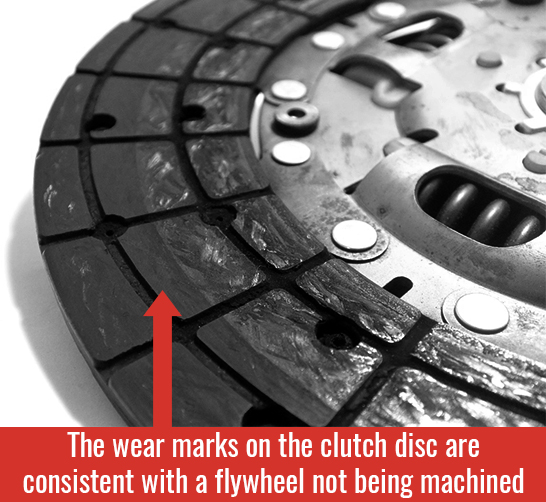

Clutch Shudder

Indicator:

Clutch Shudder

Effect:

The vehicle has a severe shudder on take-off or/and between gear changes

Cause:

1. If a new clutch has been fitted the flywheel must have been machined-If it has not, then this may cause the shudder (please note: flywheels which are not machined may affect the clutch warranty)

2. Incorrect flywheel machining (i.e machined on a lathe)

3. The clutch disc may have oil/grease contamination

4. Engine and/or gearbox mounts are worn or damaged

5. Incorrect bedding in procedure

Action:

1. Check engine and gearbox mounts-repair or replace as necessary

2. Check for any engine or gearbox oil leaks that can impact on the clutch (rear main seal, rocker cover or front gearbox seal)-repair as necessary

3. All new clutch components must be in service for a minimum of 1,000 kilometres of normal driving for efficient bedding in.

Complete Loss of Drive

Indicator:

Complete Loss of drive

Cause:

1. The clutch centre has had a total failure

2. The linings have come off the clutch disc

Effect:

The clutch is unable to transfer the engine power through the driveline.

Action:

1. Remove gearbox

2. Identify the reasons for the failure (see Trouble Shooting Clutch Disc Loss of Drive)

3. Replace clutch kit and renew (machine flywheel) or replace any other clutch service components (spigot/dual mass)

Vibration/Noise on start-up and with acceleration and de-acceleration

Indicator:

Vibration/Noise on start-up and with acceleration and de-acceleration

Cause:

The worn dual mass flywheel is causing vibration/noise

Effect:

1. There is a harsh noise and/or vibration when the vehicle is started or when shut down

2. There is a harsh noise and/or vibration when the vehicle is revved or under de-acceleration

Action:

1. Assess the vehicle loads and conditions the vehicle is being used for.

Difficulties with clean gear selection

Indicator:

Difficulties with clean gear selection (including when a new clutch has been fitted).

Cause:

1. The release of the clutch is insufficient (this will give a low clutch engagement)

2. The clutch hydraulics are preventing the clutch to operate efficiently

3. The clutch control system is not operating correctly allowing correct release (fork, pivot ball, operating cable etc)

Effect:

The clutch disc is not released correctly and still driving the gearbox

Action:

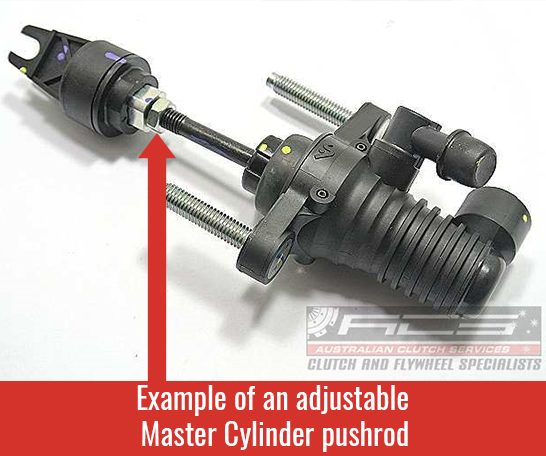

1. Assess the master cylinder adjustment (most have an adjustable push rod to lengthen the operating stroke)

2. Bleed the system to remove any trapped air (bleeding tools may be required to bleed correctly)

3. Assess the operating mechanisms to ensure they are serviceable an allowing the clutch to have optimum travel.

Noise or squeak coming from the bellhousing area

Indicator:

Noise or squeak coming from the bellhousing area

Cause:

Poorly lubricated Clutch Fork, Pivot Ball, Bearing to Fork contact face or Bearing guide tube (Incorrect release bearing failure diagnosis)

Effect:

1. These noises will be identified when the clutch is engaged (foot off the pedal).

2. To check with the vehicle running and foot off the clutch, if the noise is present apply the clutch – if the noise disappears then the likelihood of the bearing being at faulty is low. Please see below for remedy.

3. To double check the problem lubricate the clutch fork/pivot ball and back of the bearing with some spray lubrication. If the noise has disappeared then the likelihood of a bearing failure is eliminated. Please note spray lubrication is only a short term solution and the noise will come back with use. Please also be careful not to over lubricate the release components as it may compromise the clutch operation

Action:

1. Remove the gearbox. Inspect all clutch control components – Repair or replace if necessary

2. Clean and lubricate all moving components in the clutch operation system. ACS recommends SPG3 lubricating grease which is available from your local distributor.

Cracked CSC Bearing Guide/Base

Indicator:

Concentric Slave Cylinder (CSC) leaking/No pedal

Cause:

1. Incorrect mounting procedure (over torqued bolts or bolts missing)

2. CSC Misalignment (CSC off centre axis)

3. Spigot bearing/Bush damaged or missing

Effect:

Cracked CSC bearing guide/base

Action:

1. Replace CSC

2. Ensure mounting surface is clean and free of any debris

3. Replace any worn or missing bolts

4. Torque the mounting bolts to the manufacturers specifications

5. Replace spigot bearing/bush if necessary

Commercial Clutch Brake Not Working

Indicator:

No dis-engagement

Cause:

Clutch brake not operating (Pull-Type Commercial Clutch)

Effect:

1. Worn cross shafts

2. Worn cross shaft bushes in bellhousing

3. Worn or damaged clutch fork

4. Excessive wear on release bearing housing

Action:

1. Replace clutch kit

2. Replace cross shafts

3. Replace cross shaft bushes

Worn Release Bearing Thrust Face

Indicator:

Noise and rough pedal action

Cause:

1. Excessive misalignment of the release bearing

2. Excessive pre-load of the release bearing

Effect:

Worn release bearing contact face

Action:

1. Replace release bearing/Clutch kit

2. Check all clutch control components for service – if worn replace (bearing carrier, clutch for, gearbox nose cone, CSC mounting surface)

3. Incorrect clutch control setting – Incorrect (mechanical) or clutch master cylinder setting

Poor Lubrication of Release Bearing

Indicator:

Noise or squeak when the clutch is engaged (foot off the clutch)

Cause:

1. Poor lubrication of the release bearing and clutch fork contact points

2. Poor lubrication of the pivot ball/cross shaft

3. Worn/Damaged clutch fork

4. Worn/Damaged pivot ball/cross shaft

Effect:

The bearing has fatigue due to the metal on metal operations

Action:

1. Check the bearings operation for noise – if necessary replace

2. Lubricate all contact points (fork to bearing contact points, pivot ball, cross shaft)

3. Inspect all clutch control components and if necessary replace or repair.

Incorrect Bearing Fitment

Indicator:

Noise upon engaging and disengaging the clutch

Cause:

1. The bearing has been fitted to the carrier incorrectly (wrong way around)

Effect:

Total failure of the release bearing/clutch finger wear

Action:

1. Replace the bearing/clutch kit

2. Ensure the bearing is fitted to the carrier correctly

Clutch Thrust Bearing Bent

Indicator:

Release Bearing Noise & Pedal Vibration

Cause:

1. Incorrectly fitted press on release bearing to the carrier

Effect:

Bent Release bearing

Action:

1. Replace release bearing

2. Use a fitting tool to fit the bearing to the carrier

CSC Body Cracked

Indicator:

Poor performance of the Concentric Slave Cylinder (CSC)

Cause:

1. Incorrect mounting procedure (Incorrect torque)

2. Mounting surfaces not clean and free of debris

3. Poor handling techniques (dropped)

Effect:

CSC body is cracked

Action:

1. Replace CSC

2. Ensure the mounting surfaces are clean and free from any contaminants/debris

3. Always handle the CSC with care

Bearing Mis-alignment

Indicator:

Noise upon application

Cause:

1. Assembled incorrectly

Effect:

The bearing is not aligned on the Concentric Slave Cylinder (CSC)

Action:

1. Replace CSC

CSC Rear Seal Dislodged

Indicator:

Concentric Slave Cylinder (CSC) leaking

Cause:

1. Incorrect handling procedure

2. Incorrect fitment to the transmission

Effect:

The CSC rear seal has become dislodged

Action:

1. Locate the CSC correctly

2. Ensure all mounting surfaces are clean and free of debris

3. Torque the bolts to manufacturers specifications

CSC Exceeds Maximum Stroke

Indicator:

Concentric Slave Cylinder (CSC) leaking

Cause:

The CSC has exceeded maximum stroke

Effect:

1. Master cylinder failure

2. Incorrect clutch free travel

3. Incorrect bleeding practices

Action:

1. Replace CSC

2. Inspect Clutch Master Cylinder – replace if necessary

3. Adjust clutch free travel to manufacturers specifications

4. Follow the ClutchTech bleeding procedure (In some cases the CSC will need to be bleed with a reverse type vacuum bleeder)

Cracked CSC

Indicator:

Concentric Slave Cylinder (CSC) leaking/No pedal

Cause:

1. Incorrect mounting procedure (over torqued bolts or bolts missing)

2. Poor bleeding procedure

3. Pipe/Feed line obstructions leading into the CSC

Effect:

Cracked CSC body

Action:

1. Replace CSC

2. Replace any worn or missing bolts

3. Torque the mounting bolts to the manufacturers specifications

4. Ensure the inlet line is free from obstructions.

5. Always follow ClutchTech bleed procedure (in some cases a reverse vacuum bleed may be required)

Thrust Bearing Broken Lug

Indicator:

The clutch is noisy and the pedal can be slack.

Cause:

• A lug has broken

• Another fault in the mechanical operation of the clutch has caused the lug to break.

• For example, the fork is out of shape or badly positioned at the time of assembly.

Effect

A locating lug on the release bearing has broken.

Action

Check the fork and the guide sleeve and replace if signs of wear present. Ensure components are lubricated. Carefully check the clutch cable.

Premature Dual Mass Flywheel Failure

Indicator:

Dual Mass Flywheel Vibration/Knocking/Noise and beyond tolerance

Cause:

1. Multiple fault codes

2. Power/Battery Unit Failure

3. Fuel error i.e Injector or injector pump failure

4. Drivetrain has been submerged in water

5. Power increase to vehicle

Effect:

Vibration/Knocking noise on start-up/shut down and/or acceleration or de-acceleration.

Action:

1. Clear all fault codes

2. Check power unit

3. Check fuel system

4. Reseal gearbox to watertight (boots, inspection plates and any other openings)

5. Replace Dual Mass Flywheel

Thermal Loading

Indicator:

Clutch Slipping

Cause:

1. Overloading the clutch causing excessive thermal loading

2. Overloading the vehicle causing excessive heat transfer

3. Driver error

Effect:

Premature clutch wear/poor clutch performance

Action:

1. Replace/machine flywheel (Dual Mass Flywheels cannot be machined)

2. Driver education

Dual Mass Flywheel Slipping

Indicator:

Clutch Slip/No drive

Cause:

1. Dual Mass Flywheel exceeds manufacturer’s specifications

2. Dual Mass arc springs have failed

Effect:

The Dual Mass secondary surface (disc operating surface) spins on the primary (mounting) surface.

Action:

1. Replace Dual Mass Flywheel

Excessive Runout on Flywheel

Indicator:

Clutch Slipping

Cause:

1. Poor machining practices

2. Not machining or replacing the flywheel when fitting a new clutch

3. The flywheel has been exposed to excessive thermal overload

Effect:

Worn flywheel/Running face not true and flat

Action:

1. Replace clutch kit and machine/replace flywheel

2. After machining check to make sure the step (if required) is correct and the surface is flat.

Glazed Pressure Plate Surface

Indicator:

Shudder/Judder

Cause:

1. Excessive heat generated within the clutch components - Overloading the clutch

2. Carrying excessive loads - Overloading the vehicle

3. Incorrect clutch free travel

4. Incorrect driving practices (Riding the clutch)

5. Poor flywheel grinding surface finish

Effect:

Pressure plate surface and/or the flywheel surface are excessively glazed and has a mirror type finish.

Action:

1. Replace clutch kit

2. Check clutch control mechanisms and if necessary repair or replace.

3. Correct clutch free travel settings

3. Driver education

De-Adjusted SAC

Indicator:

Poor pedal feel/Clutch Slipping

Cause:

1. The clutch kit is worn beyond its service life

2. Incorrect installation

3. Incorrect clutch free travel settings

4. Faulty clutch hydraulics

5. Incorrect flywheel step

Effect:

Clutch self-adjusting mechanism has moved to its fully worn out position.

Action:

1. Replace Clutch Kit

2. Check clutch hydraulics and repair or replace if necessary

3. Set correct clutch free travel

4. Verify correct flywheel step

5. Use self-adjusting fitting tool for the fitting process

A guide for installing a self-adjusting clutch cover can be found here.

Worn Diaphragm

Indicator:

Slipping/Poor clutch engagement or dis-engagement/Metallic Noise at the bottom of the pedal

Cause:

Insufficient clearance between the release bearing and the clutch operation spring

Effect:

1. Clutch diaphragm spring has excessive wear

2. Clutch diaphragm spring has broken

3. Release bearing shows signs of fatigue (notchy or seized)

Action:

1. Replace clutch kit

2. Inspect the clutch operating system and repair or replace if necessary (Pivot Ball, Release Fork, Cross Shafts, Master Cylinder, Slave Cylinder, Clutch Cable and Pedal Box).

3. Set correct clutch free travel

Worn Facing Fibres

Indicator:

Slipping clutch/Incorrect clutch operation

Cause:

1. Bell housing has not been degreased and cleaned. Poor installation of the new clutch. The new clutch disc has not worn but fibres have become lodged in the new clutch cover are that of the previously worn clutch. It is a requirement due to ventilation designs that the bell housing area free from old fibres, dirt and grease when installing new clutch.

2. This problem is common in 4 wheel drive vehicles when an inspection cover or a clutch fork cover boot has not been Inspected for re-use or replaced when installing a new clutch.

Effect:

Worn clutch disc facing fibres and/or dirt lodged between diaphragm spring and clutch cover housing causing loss of cover clamping force.

Action:

1. Ensure the bell housing and back of the engine are thoroughly degreased and cleaned of foreign material before installing a new clutch.

2. Ensure inspection locations are sealed correctly with any boots thoroughly inspected for re-use and if necessary replaced. (Note: These problems are common on farm vehicles, vehicles travelling on sand and 4x4 recreational vehicles.)

Hold Down Bolts

Indicator:

Clutch Slipping/Noisy in operation

Cause:

Pressure plate assembly hold down bolts have not been removed after the pressure plate has been mounted and torqued to the flywheel.

Effect:

1. Hold down/Shipping bolts not removed and slipping when a new clutch has been installed

2. Unable to get correct clutch free travel adjustment

3 Unable to get correct clutch operation

Action:

Remove hold down bolts (Do not remove or adjust the clutch lever adjustment nuts/bolts)

Contamination of Friction Surfaces

Indicator:

Slipping clutch/Judder.

Cause:

1. Excessive grease used upon installation (Bearing Slide and/or shaft splines)

2. Incorrect lubricant

3. Rear main seal leak

4. Front gearbox seal leak

5. Poor practice of cleaning the clutch components prior to installation.

Effect:

Oil/Grease or other contaminants on the friction surfaces.

Action:

1. Replace Clutch kit

2. Lightly grease spline, wipe off excessive grease after tentative installation and ensure there is smooth sliding of clutch disc on main drive shaft.

3. Remove any excessive grease from the bearing slide after tentative installation.

4. Clean pressure plate surface and flywheel surface with a non-oil based solvent (Mentholated Spirits, Thinners or Brake Clean)

5. Inspect all engine and gearbox seals and if necessary replace.

Grease on Friction Surfaces

Indicator:

Slipping clutch/Judder.

Cause:

1. Excessive grease used upon installation (Bearing Slide and/or shaft splines)

2. Incorrect lubricant

3. Rear main seal leak

4. Front gearbox seal leak

5. Poor practice of cleaning the clutch components prior to installation.

Effect:

Oil/Grease or other contaminants on the friction surfaces.

Action:

1. Replace Clutch kit

2. Lightly grease spline, wipe off excessive grease after tentative installation and ensure there is smooth sliding of clutch disc on main drive shaft.

3. Remove any excessive grease from the bearing slide after tentative installation.

4. Clean pressure plate surface and flywheel surface with a non-oil based solvent (Mentholated Spirits, Thinners or Brake Clean)

5. Inspect all engine and gearbox seals and if necessary replace.

Pressure Plate Oil Contamination

Indicator:

Shudder

Cause:

1. Poor cleaning practices when fitting

2. Excessive grease used on the bearing slide and/or splines

3. Rear engine seal failure

4. Front gearbox seal failure

Effect

Oil or grease contamination on the cover and operating surfaces.

Action:

1. Replace clutch kit

2. Clean all components prior to fitment removing all lubricants and protective coatings.

3. Remove any excessive grease from the spline and/or thrust bearing after installation.

4. Replace rear engine seal if necessary

5. Replace front gearbox seal if necessary

Glazed Pressure Plate Surface

Indicator:

Shudder/Judder

Cause:

1. Excessive heat generated within the clutch components - Overloading the clutch

2. Carrying excessive loads - Overloading the vehicle

3. Incorrect clutch free travel

4. Incorrect driving practices (Riding the clutch)

5. Poor flywheel grinding surface finish

Effect:

Pressure plate surface and/or the flywheel surface are excessively glazed and has a mirror type finish.

Action:

1. Replace clutch kit

2. Check clutch control mechanisms and if necessary repair or replace.

3. Correct clutch free travel settings

3. Driver education

Worn Diaphragm

Indicator:

Pedal graunch-erratic feeling when depressing clutch pedal with engine running but ok when not running/notchy clutch pedal.

Cause:

Excessively worn diaphragm fingers

Effect:

1. Eccentricity between the axis of rotation of the clutch cover pressure plate and assembly and that of the clutch thrust bearing.

2. Worn release bearing sleeve carrier, clutch fork or pivot ball/cross shaft

3. Incorrect clutch free travel

4. Clutch control mechanism failure (Hydraulic/Cable or Linkage)

Solution:

1 Check engine to gearbox dowels and replace if necessary

2 Check the gearbox nose cone for wear and repair or replace if necessary

3 Check clutch fork and pivot ball/cross shaft and repair or replace if necessary

4 Adjust free travel to manufacture’s specification

5 If available use self-aligning bearing

Bearing Retainer Clip

Indicator:

No pressure at clutch pedal (after installation of a Pull-Type clutch)

Cause:

1. Incorrect fitting procedure

2. Damaged bearing retainer clip upon installation

3. Incorrect clutch for orientation

4. Poor handling procedure

Effect:

Bearing not located in pressure plate

Action:

1. Replace bearing clip/Cover

2. Show care when fitting the clutch and installation of the gearbox

3. Ensure the clutch fork is fitted in the correct direction

4. Show care when handling the covers ensuring never to pick the clutch up by its centre

Burst Pressure Plate

Indicator:

Loss of drive

Cause:

Clutch casting has had a total failure

Effect:

1. Excessive thermal overload

2. Incorrect driving practices

3. Clutch control failure

4. Driver error

Action:

1. Replace clutch kit

2. Check clutch control mechanisms and repair or replace if necessary

3. Driver education

Bent Straps

Indicator:

Unable to dis-engage the clutch

Cause:

1. Improper driving practice.

2. Sudden down changing of gears i.e. 5th gear to 2nd gear.

3. Constant “dropping” of clutch at extremely high RPM when taking off.

4. Poor handling/shipping practises

Effect:

Bent drive/lifting straps

Action:

1. Renew clutch kit

2. Driver education

Warped Clutch Cover

Indicator:

Slipping/Poor clutch performance

Cause:

1. Excessive heat caused the pressure plate surface fatigue.

2. Only replaced the clutch disc and pressure plate was not assessed.

Effect:

Warped clutch cover pressure plate assembly

Action:

1. Replace the clutch kit

Retractor Clip Dislodged/Stretched

Indicator:

No gear selection/difficult engagement

Cause:

Retractor clip has become dislodged/stretched

Action:

1. Over adjustment of clutch has caused the stretching of the retractor clip

2. The pressure plate has been dropped

3. The pressure plate has been damaged in transit

Action:

1. Replace clutch cover

2. Inspect the clutch operating adjustments

3. Always practice safe handling of the cover when fitting

4. Inspect the clutch cover prior to fitment to ensure there are no retractor clip issues.

Worn Clutch Disc Facing and/or Dirt Lodged Between Diaphragm Spring & Clutch Cover

Indicator:

Slipping clutch/Engagement and Dis-Engagement Problems

Cause:

- Bell housing has not been degreased and cleaned. Poor installation of the new clutch. The new clutch disc has not worn but fibres have become lodged in the new clutch cover are that of the previously worn clutch. It is a requirement due to ventilation designs that the bell housing area free from old fibres, dirt and grease when installing new clutch.

- This problem is common in 4 wheel drive vehicles when an inspection cover or a clutch fork cover boot has not been Inspected for re-use or replaced when installing a new clutch.

Effect:

Worn clutch disc facing fibres and/or dirt lodged between diaphragm spring and clutch cover housing causing loss of cover clamping force.

Action:

- Ensure the bell housing and back of the engine are thoroughly degreased and cleaned of foreign material before installing a new clutch.

- Ensure inspection locations are sealed correctly with any boots thoroughly inspected for re-use and if necessary replaced. (Note: These problems are common on farm vehicles, vehicles travelling on sand and 4x4 recreational vehicles.)

Difficulties engaging gears. Noise when clutch is engaged

Cause:

1. Severe misalignment.

2. Poor bush lubrication (insufficient oil in the bush

Effect:

Damaged spigot bush/bearing

Action:

1. Replace spigot bush

2. Check engine to gearbox dowels - replace if necessary

3. "Sweat" bronze bushes in oil if necessary.

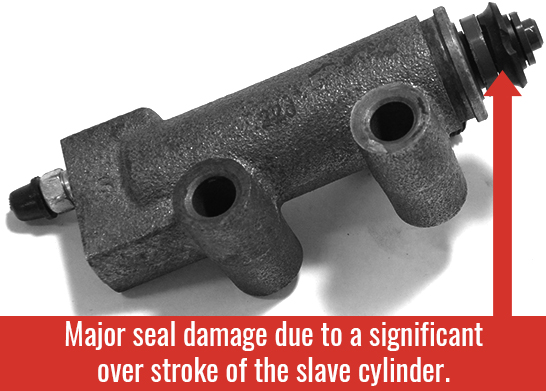

Slave Cylinder Seal Failure

Indicator:

Clutch slave cylinder leaking

Cause:

1. The slave cylinder has exceeded maximum stroke causing the seal to be exposed past its operating bore

2. Contaminated fluid – Moisture (causes rust), Fine particles (causes seal fatigue)

Effect:

Damage to the main seals of the slave cylinder

Action:

1. Replace slave cylinder/main seals

2. Check the master cylinder operation to ensure it is not over stroking the slave cylinder

3. Flush the clutch hydraulic system

Inconsistent Pedal Feel/ Clutch Master Cylinder Failure

Indicator:

Inconsistent pedal feel/Clutch Master Cylinder failure

Cause:

Contaminated or old clutch fluid

Effect:

1. Master cylinder leaking

2. Damage to the main internal seals (causing a bypass)

3. Moisture in the clutch fluid

Action:

1. Replace clutch master cylinder – if necessary

2. Replace the hydraulic fluid (only use manufactures specified fluid)

3. Flush the clutch hydraulic system completely to remove any residual contamination.

Worn Disc Linings

Indicator:

Clutch slipping

Cause:

1. Clutch control failure

2. Linings have been exposed to excessive heat.

Effect:

Clutch disc linings worn out

Action:

1. Replace clutch disc/kit

2. Check clutch operating mechanisms

3. Set clutch free travel to manufacturers specifications

Broken Facings

Indicator:

Slipping/Shudder/Judder - Poor clutch performance

Cause:

1. Overloading the clutch

2. Overloading the vehicle

3. Clutch disc has been over torqued (Changing from 5th to 2nd at high speed)

Effect:

Broken clutch lining

Action:

1. Replace clutch disc/kit

2. Driver education

Difficulties disengaging gear/Slipping

Cause:

1. CSC operating off axis (mis-aligned)

2. Incorrect mounting of the CSC (Incorrect torque or bolts missing)

Effect:

Concentric Slave Cylinder (CSC) internal piston not travelling smoothly causing a system failure

Action:

1. Replace CSC

2. Make sure the CSC mounting surfaces are free from debris, grime and any sealants (please note sealants should not be used unless the manufacturer has specified to do so - this will cause the CSC to mount off axis)

3. Check and Inspect mounting bolts - if necessary replace

4. Torque to manufacturers specifications.

-malfunction01.jpg)

-malfunction02.jpg)

Burst Facings

Indicator:

Loss of drive/no transmitted power

Cause:

1. The clutch disc has had a torque overload (i.e 5th to 2nd at high speed)

2. Clutch control failure (Clutch hydraulics/Clutch cable)

3. Incorrect clutch free travel

4. Overloading the clutch

5. Overloading the vehicle

Effect:

The clutch disc linings have had a total failure

Action:

1. Replace the clutch disc/kit (ensure all fibrous material is removed from the gearbox and back of engine)

2. Check and inspect all clutch control mechanisms - repair or replace if necessary

3. Set clutch free travel to manufacturer’s specifications.

4. Driver education

Burnt Facings

Indicator:

Slipping/Lost Drive

Cause:

1. Oil or grease contamination on the clutch disc

2. Faulty clutch release system

3. Incorrect clutch free travel

4. Overloading the clutch

5. Overloading the vehicle.

Effect:

Linings have deteriarated or missing due to excessive clutch slip

Action:

1. Replace the clutch kit and machine the flywheel

2. Check and assess all oil seals – replace if necessary

3. Thouroughly inspect all release mechanism components (fork, pivot ball, pedal box, cross shafts, clutch hdraulics/release cables)

4. Set clutch free travel to manufacturer’s specifications.

5. Driver eductaion

Disc Contamination

Initiator:

Slipping Clutch/Shudder or Judder

Cause:

1. Rear main engine seal failure/fatigue

2. Front gearbox seal failure/fatigue

3. Excessive lubrication on the clutch disc splines/gearbox nose cone/release bearing

Effect:

Oil or Grease contamination on the clutch disc linings

Action:

1. Replace the clutch disc/kit

2. Inspect the rear main seal for leaking – replace if necessary

3. Inspect front gearbox seal – replace if necessary

4. Inspect any other engine oil leaks which could compromise the gearbox bellhousing (i.e sump gasket, rocker cover etc)

5. Remove any excessive lubrication from the clutch components once they have been checked for compatibility.

Over Lubrication of Friction Disc

Indicator:

Clutch Slipping/Shudder or Judder

Cause:

1. Excessive use of grease when lubricating the components on assembly.

Effect:

Clutch disc linings are contaminated with grease/oil

Action:

1. Replace clutch disc

2. Remove any excess grease from the clutch components after they have been checked for compatibility

Flywheel has not been machined

Indicator:

Clutch Shudder/Judder

Cause:

1. Un-machined flywheel (not even/warped)

2. Poor flywheel grinding practices (machined on a lathe)

Effect:

Vehicle vibrates when the clutch is released

Action:

1. Surface grind the flywheel

2. Check the machining surfaces are true and parallel

Fused Friction Material

Indicator:

Non-release/Shudder

Cause:

1. The clutch disc has exceeded maximum temperature.

2. The flywheel was not machine when the new clutch was installed

3. Overloading the clutch disc (excessive clutch "kicks" or launching)

Effect:

Ceramic friction material has fused to the flywheel

Action:

1. Replace the clutch disc

2. Always machine the flywheel when fitting a new clutch

3. Driver education

Wrong Friction Disc

Indicator:

Noisy/No disengagement

Cause:

1. Not checking part suitability when installing the clutch

2. Incorrect disc for application (disc only replacements which do not suit the cover)

Effect:

Clutch disc does not suit the clutch cover

Action:

1. Replace kit to a matched kit

2. Education for clutch installer

Spring & Stop Pin Damage

Indicator:

Loss of dive/Poor clutch performance/Noisy in operation

Cause:

1. Engine to gearbox dowels missing or damaged

2. Gearbox and/or engine mounting face damaged or have high levels of contamination

3. Obstructions between engine and gearbox mounting face preventing the gearbox to be flush to the engine when mounted.

4. Missing/damaged or incorrectly torqued gearbox mounting bolts

5. Clutch disc overload (Changing from 5th to 2nd at high speed)

6. Excessive RPM load (Launching the vehicle at high RPM)

Effect:

Clutch disc damper springs have become dis-lodged and stop pins are damaged

Action:

1. Replace clutch kit

2. Replace gearbox dowels

3. Ensure the gearbox and engine mating surfaces are free from contamination.

4. Ensure there are no obstructions between engine and gearbox when final torqueing of the gearbox mounting bolts

5. Replace worn or damaged gearbox mounting bolts if necessary

6. Driver education

Broken Damper Springs

Indicator:

Loss of dive/Poor clutch performance

Cause:

1. Engine to gearbox dowels missing or damaged

2. Gearbox and/or engine mounting face damaged or have high levels of contamination

3. Obstructions between engine and gearbox mounting face preventing the gearbox to be flush to the engine when mounted.

4. Missing/damaged or incorrectly torqued gearbox mounting bolts

Effect:

Clutch disc failure due to mis-alignment (gearbox centre off-axis to crankshaft)

Action:

1. Replace clutch kit

2. Replace gearbox dowels

3. Ensure the gearbox and engine mating surfaces are free from contamination.

4. Ensure there are no obstructions between engine and gearbox when final torqueing of the gearbox mounting bolts

5. Replace worn or damaged gearbox mounting bolts if necessary

Broken Drive Hub/Damaged Stop Pins

Indicator:

Noise, difficulties changing gears

Cause:

Broken drive hub on clutch disc/Damaged stop pins

Effect:

1. Severe engine to gearbox mis-alignment

2. Excessive down shifting (Changing from 5th to 2nd at high speed)

3. RPM overload of the clutch disc (High RPM launching)

Action:

1. Replace clutch disc

2. Check engine to gearbox dowels are present and in a serviceable condition (Replace if necessary)

3. Driver education.

Sudden Clutch Failure

Indicator:

Sudden Clutch Failure.

Cause:

1. Faulty or worn pilot bearings or bushing

2. Hanging gear box during installation

3. Contamination between mating surfaces of the engine bolt up areas.

4. Severe engine to gearbox mis-alignment

5. Clutch disc overload (Shifting from 5th to 2nd at high speed)

6. Transmission failure

Effect:

Clutch hub failure.

Action:

1. Check pilot bearing and replace if necessary.

2. Inspect engine to gearbox dowels are serviceable and if damaged replace

3. Align clutch to the flywheel and show care when fitting the gearbox.

4. Ensure the engine and gearbox have clean mating surfaces before installation.

5. Check gear box for metal fragments then remove and repair parts in necessary.

6. Driver education

Damaged Facing Material

Indicator:

No drive

Cause:

1. Overloading the clutch disc (example: shifting from 5th to 2nd at high speed)

Effect:

Clutch disc lining broken

Action:

1. Replace clutch disc

2. Driver education

-final.jpg)

Clutch disc splines damaged

Indicator:

Loss of drive

Cause:

1. Gearbox misaligned (gearbox to engine dowels damaged or missing)

2. Input shaft damaged

Effect:

Spline worn/damaged or missing

Action:

1. Replace clutch disc

2. Inspect gearbox to engine dowels are present and serviceable (if damaged replace)

3. Inspect the Input shaft for excessive wear and damage.

Broken Segments

Indicator:

Loss of drive/Noisy when operating the clutch pedal

Cause:

1. Clutch disc has been over torqued - example: down changing from 5th to 2nd gear at high speed

2. Severe engine to gearbox mis-alignment - Red dust will be present when alignment issues are present.

3. Clutch disc has been overloaded

4. Damaged pilot bearing/bush

5. Damaged upon fitment

Effect:

The disc outer has come off the drive hub

Action:

1. Replace the clutch disc

2. Check all engine to gearbox dowels are present and in a serviceable condition (If necessary replace)

3. Replace pilot bearing/bush

4. Show care when fitting the gearbox making sure there is no possibility of damaging the drive up causing the spring fatigue (hanging the gearbox on the clutch disc)

5. Driver education

Worn Splines

Indicator:

Difficulties changing gears

Cause:

1. Gearbox misaligned (gearbox to engine dowels damaged or missing)

2. Input shaft damaged

Effect:

Spline damaged on the clutch disc from incorrect alignment

Action:

1. Replace clutch disc

2. Inspect gearbox to engine dowels are present and serviceable (if damaged replace)

3. Inspect the Input shaft for excessive wear and damage.

Race Clutch Spline Damage

Indicator:

Difficulties changing gears

Cause:

1. Gearbox misaligned (gearbox to engine dowels damaged or missing)

2. Input shaft damaged

Effect:

Spline damaged on the clutch disc from incorrect alignment

Action:

1. Replace clutch disc

2. Inspect gearbox to engine dowels are present and serviceable (if damaged replace)

3. Inspect the Input shaft for excessive wear and damage.

Severe Misalignment Between Mating Surfaces

Indicator:

Loss of dive/Poor clutch performance

Cause:

1. Engine to gearbox dowels missing or damaged

2. Gearbox and/or engine mounting face damaged or have high levels of contamination

3. Obstructions between engine and gearbox mounting face preventing the gearbox to be flush to the engine when mounted.

4. Missing/damaged or incorrectly torqued gearbox mounting bolts

Effect:

Clutch disc failure due to mis-alignment (gearbox centre off-axis to crankshaft)

Action:

1. Replace clutch kit

2. Replace gearbox dowels

3. Ensure the gearbox and engine mating surfaces are free from contamination.

4. Ensure there are no obstructions between engine and gearbox when final torqueing of the gearbox mounting bolts

5. Replace worn or damaged gearbox mounting bolts if necessary

Disc Bent

Indicator:

Clutch fails to release/poor clutch performance

Cause:

1. Hanging the transmission on the clutch disc (not locating the gearbox over the dowels)

2. Incorrect gearbox mounting (forcing the gearbox onto the engine with the bolts)

Effect:

Bent clutch disc

Action:

1. Replace clutch disc/Clutch kit

2. Always practice safe installation of the transmission

3. Align the clutch disc to the engine with the correct clutch alignment tool.

Broken drive hub outer

Indicator:

Loss of drive/Noisy when operating the clutch pedal

Cause:

1. Clutch disc has been over torqued - example: down changing from 5th to 2nd gear at high speed

2. Severe engine to gearbox mis-alignment - Red dust will be present when alignment issues are present.

3. Clutch disc has been overloaded

4. Damaged pilot bearing/bush

5. Damaged upon fitment

Effect:

The disc outer has come off the drive hub

Action:

1. Replace the clutch disc

2. Check all engine to gearbox dowels are present and in a serviceable condition (If necessary replace)

3. Replace pilot bearing/bush

4. Show care when fitting the gearbox making sure there is no possibility of damaging the drive up causing the spring fatigue (hanging the gearbox on the clutch disc)

5. Driver education

Damaged Torsion Springs

Indicator:

Unable to disengage gears/Noisy clutch operation

Cause:

1. Clutch disc has been over torqued - example: down changing from 5th to 2nd gear at high speed

2. Severe engine to gearbox mis-alignment - Red dust will be present when alignment issues are present.

3. Damaged pilot bearing/bush

4. Damaged upon fitment

Effect:

Damaged torsion springs

Action:

1. Replace the clutch disc

2. Check all engine to gearbox dowels are present and in a serviceable condition (If necessary replace)

3. Replace pilot bearing/bush

4. Show care when fitting the gearbox making sure there is no possibility of damaging the drive up causing the spring fatigue (hanging the gearbox on the clutch disc)

5. Driver education

Contact mark on the teeth of spline and the end of hub

Indicator:

Difficult to disengage gears

Cause:

1. Poor fitting techniques (clutch disc not aligned correctly)

2. Forcing the gearbox onto the engine dowels (using bolts to force the gearbox to its mounting face)

Effect:

Damaged clutch disc splines

Action:

1. Use clutch alignment tool when fitting the clutch kit to the flywheel

2. Always show care when fitting the gearbox ensuring the clutch disc is not damaged

Clutch Broken Facing

Indicator:

Difficulties disengaging gears

Cause:

1. Clutch disc has been damaged when fitting

2. Clutch disc has been dropped

3. Clutch disc has been damaged in transit

Effect:

Damaged facing material

Action:

1. Replace the Clutch Disc/Clutch kit

2. Always show care when fitting clutch discs

3. Always thoroughly inspect the clutch components prior to fitting.

Burrs at the end of hub due to uneven wear on the spline teeth

Indicator:

Difficult to dis-engage gears

Cause:

1. Spline damaged when fitting the gearbox

Effect:

Burrs/Damage to the spline

Action:

1. Replace clutch disc

2. Align the clutch disc using clutch alignment tool

3. Use caution when fitting the gearbox ensuring no damage can occur

Crashing noise in gear box, non release, warped and bent clutch disc

Indicator:

Poor clutch dis-engagement

Cause:

- Hanging the gearbox on the clutch disc during installation.

- Not aligning clutch disc and forcing the gearbox into the spline.

- Incorrect clutch disc orientation

Effect:

Warped/Bent Clutch Disc

Action:

- Do not hang gear box during clutch installation and always use a clutch aligning tool.

- Do not force gear box into clutch disc spline.

- Do not use the gearbox mounting bolts to force the gearbox over the dowels.

- Fit the clutch disc with the correct orientation

Pressure plate- heat patched

Indicator:

Slipping/Shudder, Poor clutch performance

Cause:

- Overloading the clutch

- Overloading the vehicle

- Incorrect clutch free travel

- Clutch control failure (Hydraulic/Cable)

- Driver error

Effect:

Pressure plate casting has heat deterioration.

Action:

- Replace clutch kit and machine flywheel

- Check clutch control mechanisms and if necessary repair or replace

- Driver education

Tilted release plate

Indicator:

Non-Release (Clutch Drag)/Pedal Vibration

Cause:

- Poor fitting practices (lever strut has become dislodged when fitting)

- Clutch lever fatigue due to incorrect free travel

Effect:

Release lever plate uneven (when bolted to the flywheel)

Action:

- Replace clutch kit

- Check clutch control system and repair or replace if necessary

- Check and adjust clutch free travel

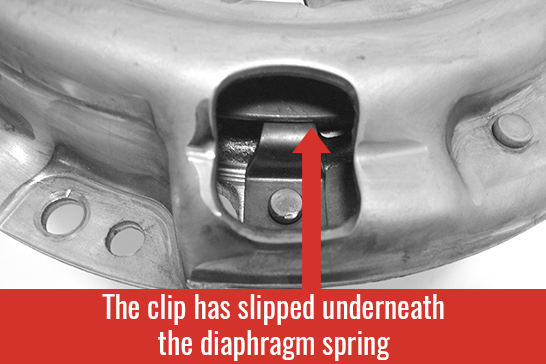

Broken Retractor Clips

Indicator:

No gear selection/difficult dis-engagement.

Cause:

Stretched and damaged retractor clip (Clip stretched above diaphragm).

Effect:

After installation of new clutch, unable to select gear.

Action:

- Fit new cover assembly

- Adjust clutch to manufacturer’s specifications.

- Always check components before fitting and ensure that the tip of retractor clip is resting on top of the diaphragm.

Diaphragm fouled on clutch disc

Indicator:

Difficult to engage/disengage gear, grating noise and hard pedal at the end of the operating stroke.

Cause:

- Flywheel depth or step incorrect

- Clutch thrust bearing has fallen off the gearbox nose cone slide.

- Clutch disc too thick

- Incorrect clutch free travel (too much pre-load)

- Faulty clutch hydraulics

Effect:

Diaphragm fouled on clutch disc. Crashing in gear and unable to obtain clutch adjustment.

Action:

- Check flywheel depth or step incorrect

- Check for wear or damage to the gearbox nose cone slide

- Check clutch disc thickness

- Check clutch hydraulics and replace if necessary

- Adjust clutch free travel to manufacturers specifications

Trouble Shooting

- Clutch Cover

-

Clutch Disc

- Difficult Disengagement(10)

- Loss of Drive(5)

- Noise & Vibration(3)

- Other(2)

- Shudder (judder)(3)

- Slipping(6)

- Clutch Master Cylinder(1)

- Clutch Slave Cylinder(1)

- Clutch Spigot Bearing, bush (pilot bearing)

-

CSC (concentric slave cylinder)

- CSC Leaking(1)

- Loss of Fluid(5)

- Other(1)

- Flywheel

- Thrust Bearing

- Vehicle Diagnostics(6)